Transporting frozen meat can be a significant challenge, especially during the hot summer months. This is because meat products are susceptible to rapid bacterial growth when exposed to lower than recommended temperatures. In fact, at just 10 degrees Celcius, the bacteria on food can double every fifteen minutes. So, to maintain quality meats and ensure your clients receive food that is safe to eat, it’s important to follow the below tips for the transportation and distribution of frozen meat.

All of these tips adhere to the Three Essential Rules of Australian Cold Chain Guidelines.

1. Follow a Process When Receiving Frozen Meat

In order to preserve the quality of frozen meat, a process should be in place when receiving frozen meat. Of course, the faster the meat gets from the supplier and into your refrigerated vehicle, the better. But you shouldn’t rush the process and risk skipping over important details. Here’s what we recommend.

- Inspect each product and box on arrival

- Ensure all frozen foods are frozen solid

- Look for evidence of thawing (fluids stains on packaging or frozen fluids)

- Ask for documentation of previous freezing temperatures

- Label and date each product so you can deliver ‘first in, first out’

Ensuring this process is followed as quickly as possible will protect the safety and the quality of products when transporting frozen meat.

2. Maintain Distribution Temperature (and keep a record!)

When transporting frozen meat, it’s so important to ensure is that a stable temperature is maintained. When temperatures fluctuate, bacteria can grow and undermine the safety of the product being transported. Because of this risk, it’s beneficial to use a calibrated thermometer to check that temperatures are holding steady at -18 degrees Celcius or lower.

If meat must be removed from the freezer storage, speed is of the essence. The general rule is to allow no more than 1 hour throughout this transition to prevent temperatures from entering the Temperature Danger Zone. The food’s temperature can be monitored with a thermometer and should be logged at frequent intervals.

Keeping a temperature record throughout the distribution process also ensures accountability of proper food storage. This log can protect your business and your employees if faced with a claim that improper food handling caused illness.

To find out more about the technology of refrigerated trucks, read our blog, How Refrigerated Trucks Work.

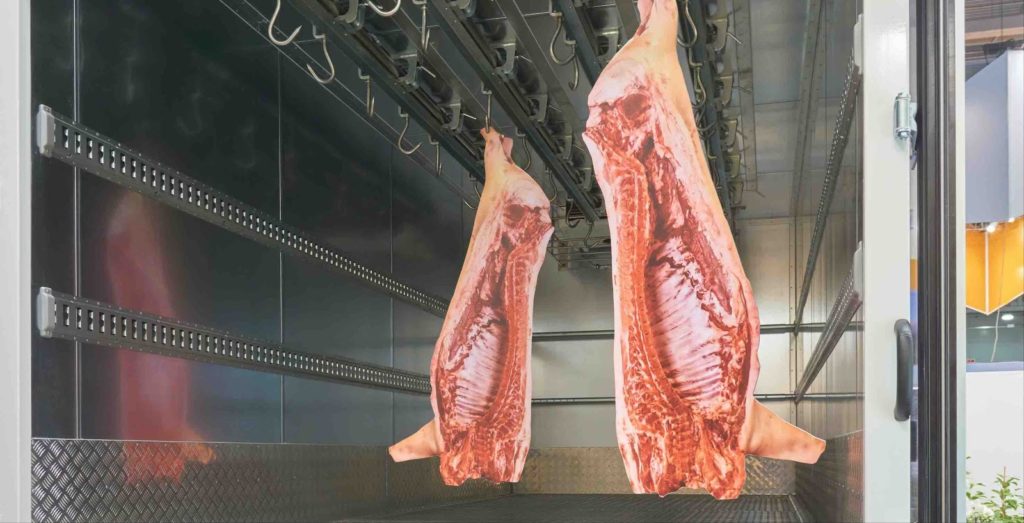

3. Maintain Air Circulation Around Boxes and Products

Whether you’re transporting frozen carcasses and primal cuts, or frozen retail cuts and minced meat, air circulation around the product is essential. Boxes should never sit flat on the floor, but instead on a pallet so air can flow underneath. For large shipments, avoid stacked pallets and use perforated boxes or meat hangers to allow cold air to circulate around the products.

Doing this helps to keep the frozen meat within critical temperature points and as a result maintains freshness, flavour and shelf life.

Contact Scully RSV For More Advice on Transporting Frozen Foods

Speed and temperature control are at the core of maintaining quality and safety when transporting frozen meat. For more information, contact Scully RSV or check out our previous blogs: